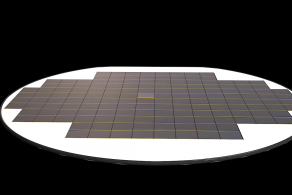

One hundred cells per each single wafer

BSQ’s High Concentration Photovoltaic System (CPV) is the perfect warhorse for the new generation of Beyond-Shockley-Queisser record-efficiency photovoltaic cells.

With more than a decade of intensive field testing and thorough development in the lab, the BSQ solar CPV system combines high efficiency, high concentration, non-imaging optics, with a simple and rugged module design especially devised for local assembly, and a truly robust and highly accurate sun tracker. Everything is optimized to provide the most cost-effective path, for the industrialization of competitive CPV electricity generation systems.

Very high concentration ratio of 820X and possibility to scale up to 1000X

Unique dome-shaped concentrating Fresnel lens with top dimple, produced by automobile headlamp manufacturer maximizes acceptance angle pointing tolerance up to 1°

Secondary optical stage based on kaleidoscopic optics, that through total internal reflection creates uniform light flux over the cell, preventing conversion losses due to chromatic aberration or inhomogeneous intensity distribution

Overall optical efficiency over 85% enables high overall conversion efficiency

Integration of high efficiency triple junction cells with 37% average efficiency by 1st tier manufacturer

Kaleidoscopic homogenizer and three junction cell, both packaged in fail-proof receiver block

Over 30 yrs lifetime for encapsulation polymers in receiver block when subject to accelerated aging under most critical conditions: concentrated UV radiation in damp heat environment

Only requires passive cooling, with cell directly laminated in receiver block onto aluminum substrate, with no need for fin heat sink

Very high concentration ratio of 820X and possibility to scale up to 1000X

Unique dome-shaped concentrating Fresnel lens with top dimple, produced by automobile headlamp manufacturer maximizes acceptance angle pointing tolerance up to 1°

Secondary optical stage based on kaleidoscopic optics, that through total internal reflection creates uniform light flux over the cell, preventing conversion losses due to chromatic aberration or inhomogeneous intensity distribution

Overall optical efficiency over 85% enables high overall conversion efficiency

Integration of high efficiency triple junction cells with 37% average efficiency by 1st tier manufacturer

Kaleidoscopic homogenizer and three junction cell, both packaged in fail-proof receiver block

Over 30 yrs lifetime for encapsulation polymers in receiver block when subject to accelerated aging under most critical conditions: concentrated UV radiation in damp heat environment

Only requires passive cooling, with cell directly laminated in receiver block onto aluminum substrate, with no need for fin heat sink